Commissioning of Graco equipment: Safety, prevention and control for proper operation

When you purchase Graco equipment for your business, one of the most important steps is to ensure that the setup is done correctly. Because? Because this process ensures that the installation is safe, that the equipment works as expected, and that you can avoid costly problems in the future. But how to ensure that everything is done correctly? Here we explain it to you step by step.

What does starting up Graco equipment entail?

Commissioning is not simply turning on the equipment. It is a meticulous procedure that includes:

- Preventive measures: Evaluate the installation location, electrical connections, safety conditions and the manufacturer's user manual.

- Safety tests: Verify that there are no leaks, that the pressure systems are stable and that the components are correctly assembled.

- Calibration: Adjust the equipment so that it meets the technical parameters established by Graco.

Performing these steps not only ensures that your equipment works at 100%, but also prevents accidents and prolongs its useful life.

Why is security key in startup?

One of the pillars of the process is security. Imagine that you start a project without checking pressure stability or without evaluating leak risks. This not only endangers operators, but can also affect the quality of work.

Some measures that are applied during this process are:

- Check connection points to avoid leaks.

- Load testing to ensure systems can handle the work needed.

- Inspection of the environment to ensure that it is safe to operate the equipment.

This is especially relevant in sectors such as painting or spraying, where Graco equipment is a leader for its precision and performance.

What specific tests are performed?

pressure test

The equipment's ability to operate under different pressure levels without failure is evaluated.

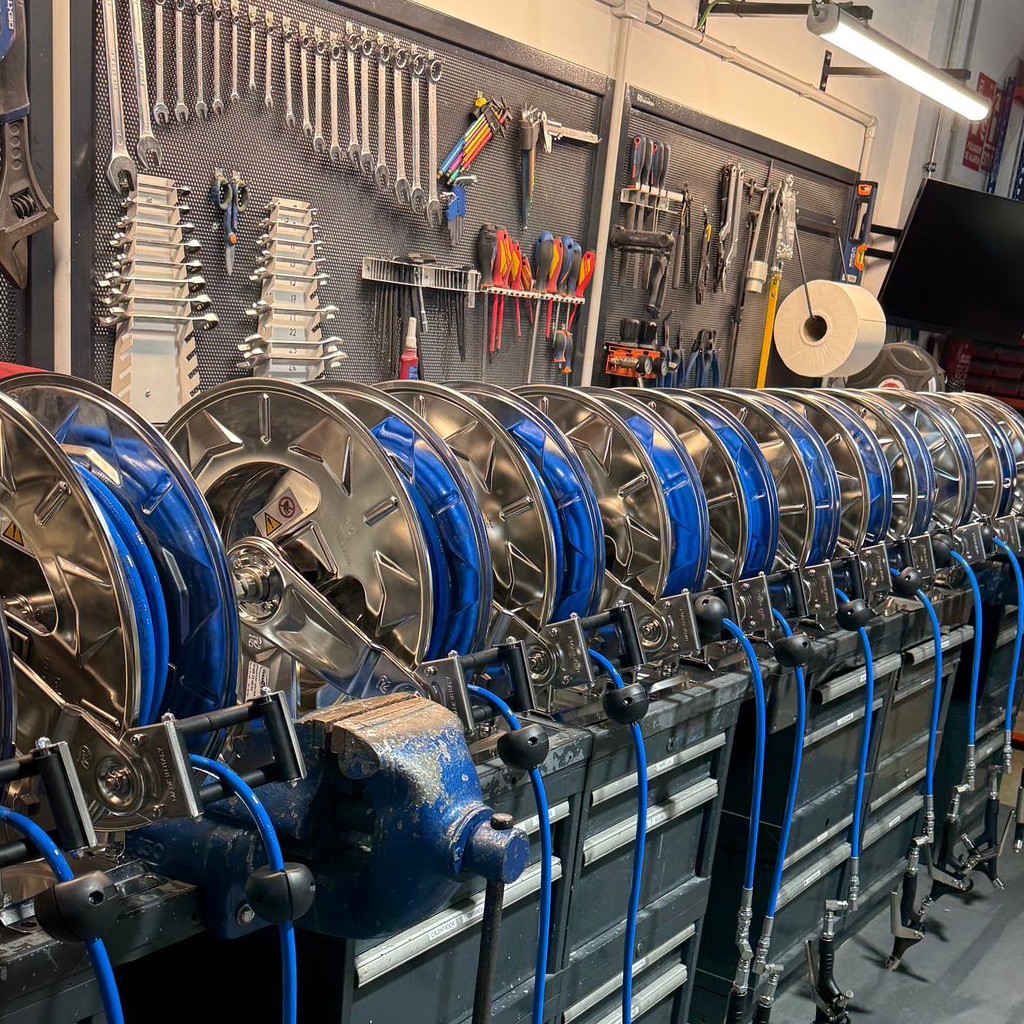

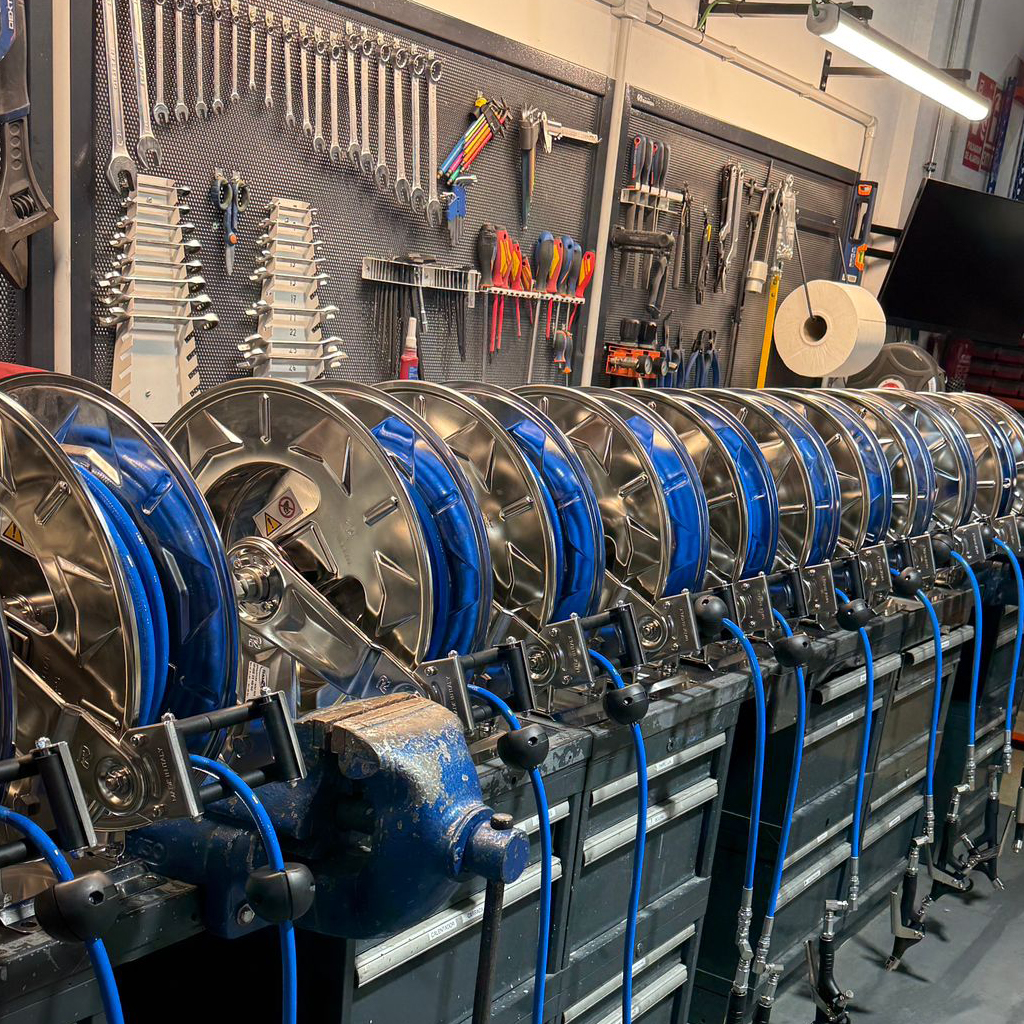

Leak test

All connections, hoses and valves are inspected to ensure there are no air, paint or liquid leaks.

Technical calibration

Flow, speed and mixing systems are adjusted to meet manufacturer standards.

These tests ensure that Graco equipment delivers maximum precision, which is vital for highly demanding industrial or commercial projects.

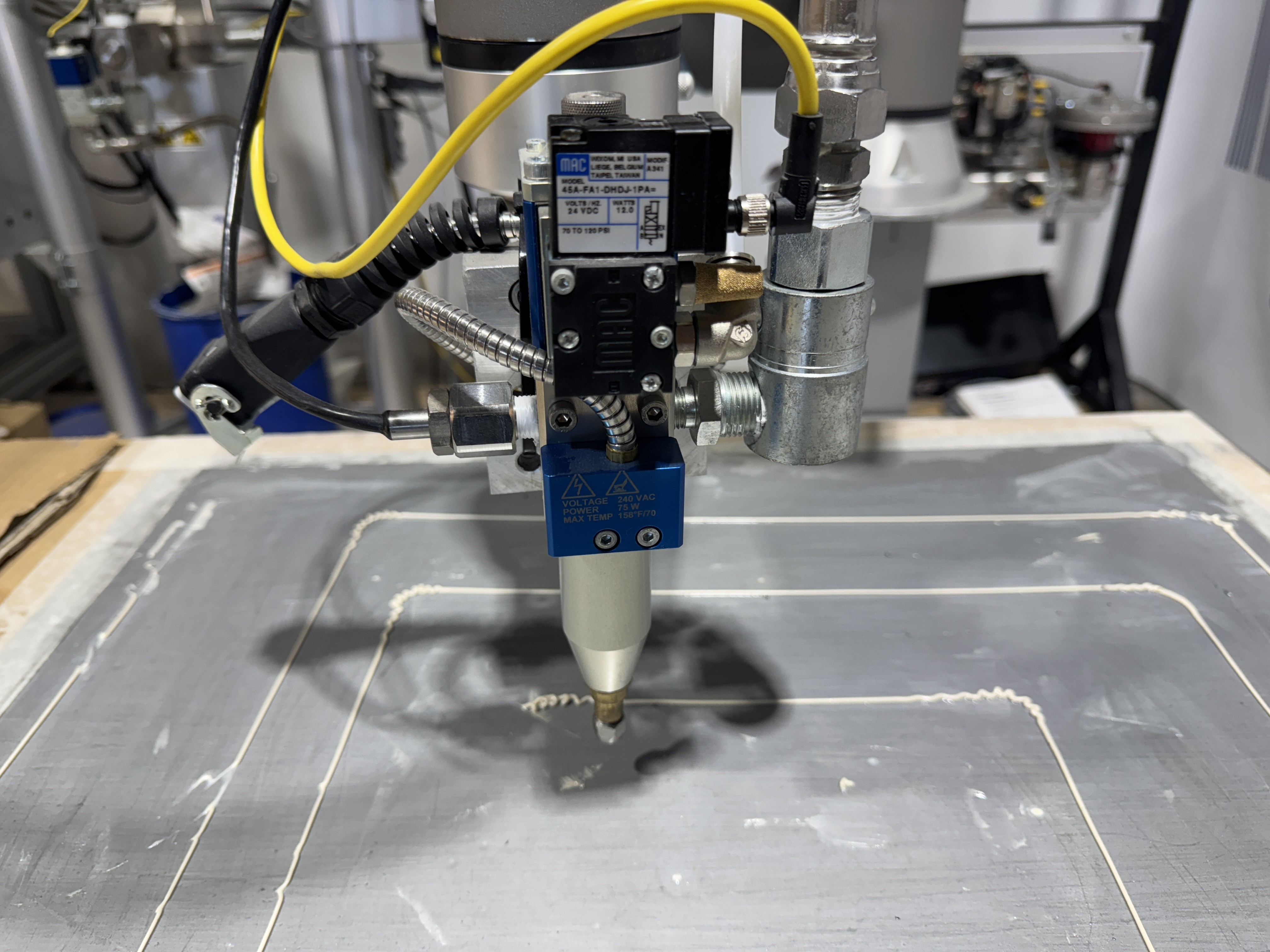

Practical example: Start-up on a Graco paint machine

Let's say you have an industrial painting business and you purchase a Graco sprayer. During start-up:

- You review the technical manual to understand the correct connections.

- You visually inspect all parts of the equipment.

- Perform controlled spray tests to verify paint pattern and pressure.

This not only ensures a perfect finish, but also avoids interruptions during your projects.

FAQs about starting up Graco equipment

The time varies depending on the equipment, but usually lasts between 1 and 3 hours.

Although you can perform some basic steps, a certified technician is recommended to ensure safety and standards compliance.

You could face problems such as equipment failure, dangerous leaks, or even irreparable damage that affects your investment.

.png)

.png)

.png)

.png)